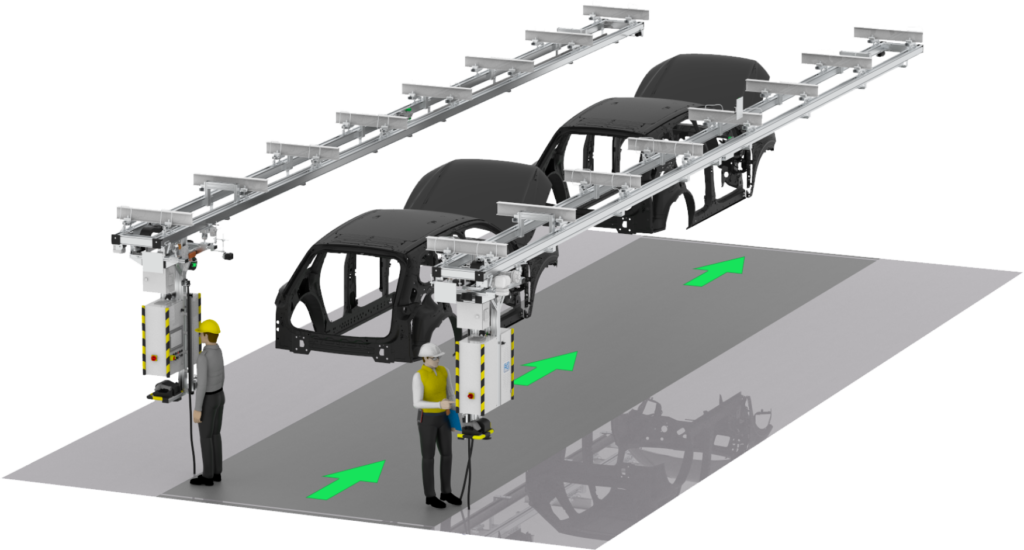

AUTOMATED AIR FILLING FOR SHOCK ABSORBERS

The LFA1012S filling device is used to fill the vehicle’s air suspension system. Each console is equipped with a traction motor and safety features. The device is located on the ML04 line in the Volkswagen Slovakia, Bratislava plant and it is possible to fill the air suspension of the VW Touareg, AUDI Q7 and AUDI Q8 with it.

LASER STATION OF PRODUCTION LABELS V2.0

The V2.0 laser marking station is used to laser TPS labels on the marking tapes, which are then glued to a designated place on the vehicle body. The station has two tape tracks and a lockable tray for TPS labels. The marking is performed using an OEM TruMark 5020 laser unit from TRUMPF.

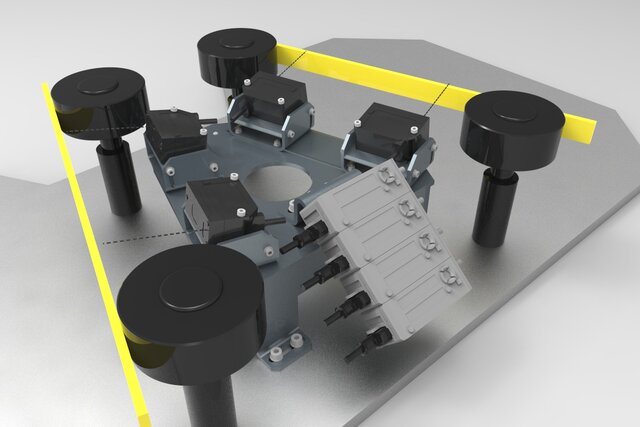

SIDE WINDOWS TYPE RECOGNITION

The device consists of several mechanical, electrical and optical parts, which are interconnected and controlled by a PLC system. The main part of the device are four optical laser sensors designed to measure distance. The sensors, together with their control units, are placed on a large mounting plate, on the table of the centering device.

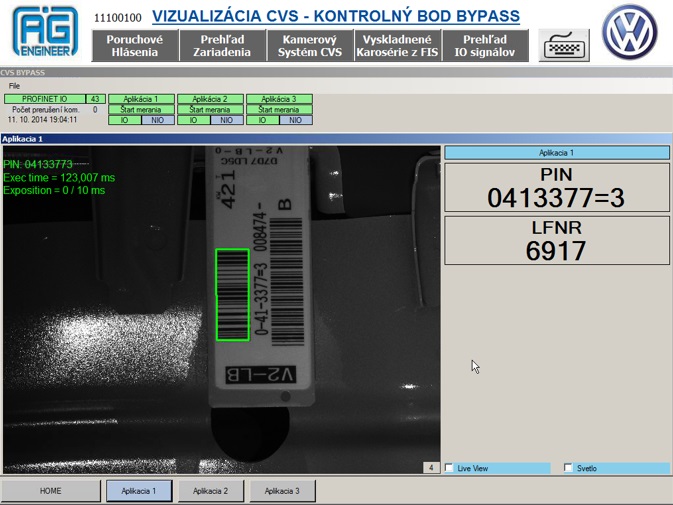

BODY TYPE RECOGNITION BY CAMERA SYSTEM

The application is used to distinguish 22 types of bodies from bodies of other types in the main tank and then move to another transport branch. When the body arrives at the checkpoint, a snapshot of the TPS label is taken. By analyzing the image, you get the PIN number of a specific body. Based on the PIN number obtained, the request is sent to the FIS database to the “Laufende Nummer” and the type of the corresponding bodywork.

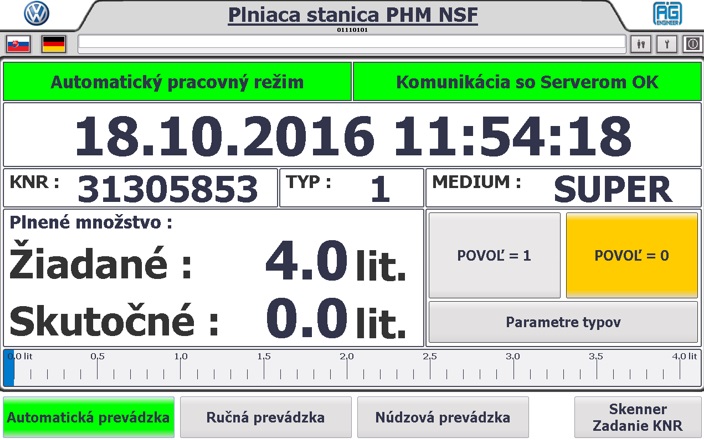

REFUELING STATION CONTROL

The NSF filling station is used for refueling NSF vehicles with SUPER and DIESEL fuels on the ML03 assembly line. It consists of a refueling stand and a switchboard on which the control panel of the SIMATIC Comfort Panel is located.

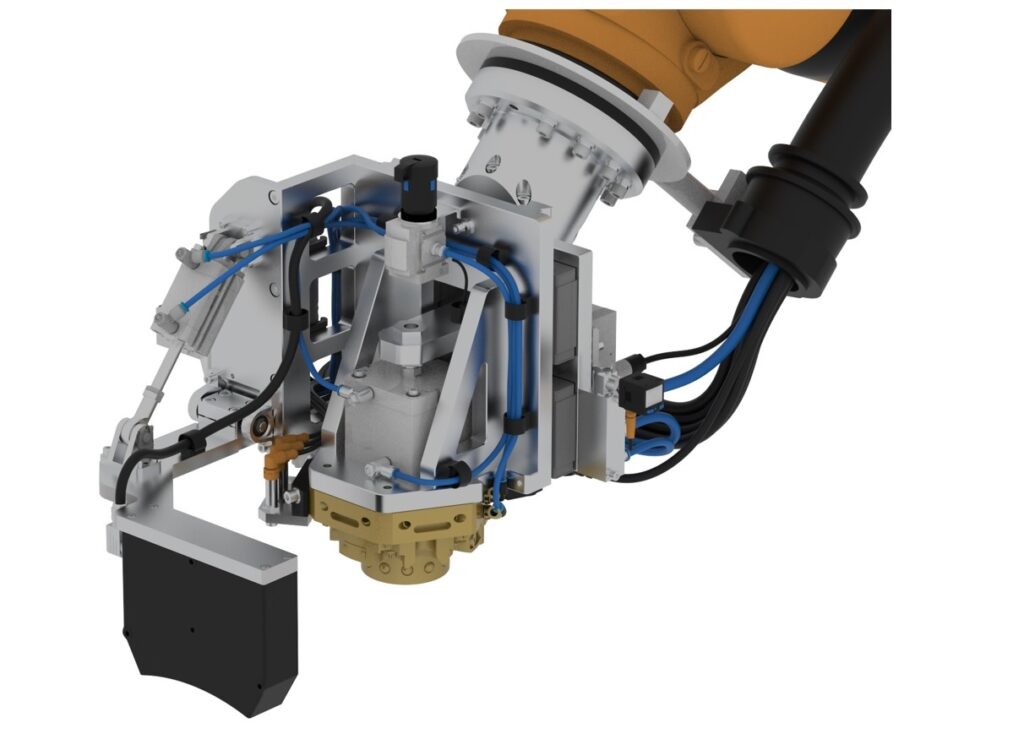

ROBOTIC CAMERA SYSTEM FOR VIN NUMBER RECOGNITION

After opening the hood with a device designed for this purpose, the robot with a camera on the tilting arm moves under the front hood, where it performs the measurement. If the camera system evaluates that the area for marking the VIN number is OK, the robot continues to operate – it moves under the hood with the marking head and do the process of marking VIN number.

EMERGENCY STRATEGY MANIPULATORS FOR VIN NUMBERS MARKING

The workplace is located in the production hall of VW Bratislava. It is used to VIN numbers marking into the body of Q8, Q7 and VW Touareg. The workplace consists of two separate manipulators. The first manipulator in the direction of travel of the line is used to stamp the VIN number into the body of AUDI Q8, the second manipulator is used to VIN number marking into the body of AUDI Q7 and VW Touareg. The devices serve as an emergency strategy, ie in the event of a failure on the automatic stamping device. The automatic VIN marking workplace is located in front of the KB line and the KUKA robot guides the tool with the punching head into the body.

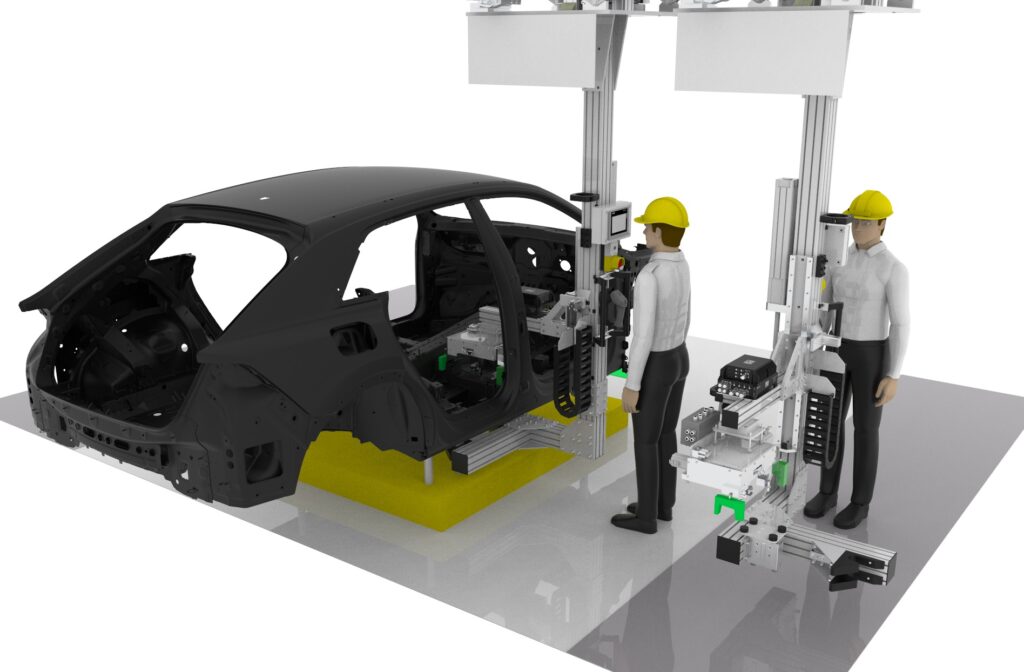

PORTABLE VIN NUMBER MARKING SYSTEM

The mobile VIN number marking system is intended for marking VIN numbers for Porsche Cayenne. The device is operated by one worker who guides the punching head by means of stops into the open body. The embossing head is on the upper movable arm and with the help of the lower arm and clamping systems it is attached to the body on which the process of embossing the VIN number is performed.