AUTOMATED AIR FILLING FOR SHOCK ABSORBERS

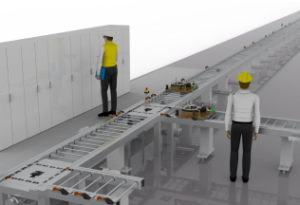

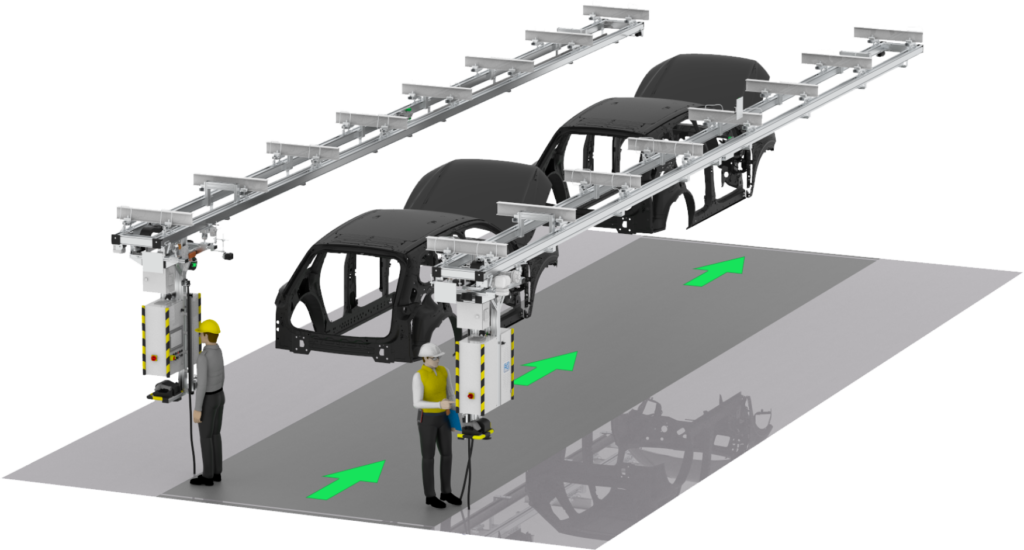

The device can be divided into several parts in terms of functionality. Next to the line, there is a main switchboard, which provides power to the filling consoles, communication with conveyor technology and control of the equipment. Next to the main switchboard there is a group of compressors + KOM, which ensure the distribution of compressed air for filling consoles. Above the line is a structure consisting of a system of running rails allowing the filling brackets to move in the direction of the X axis.

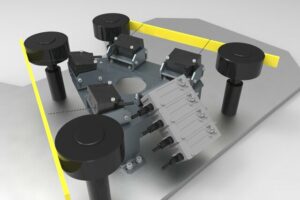

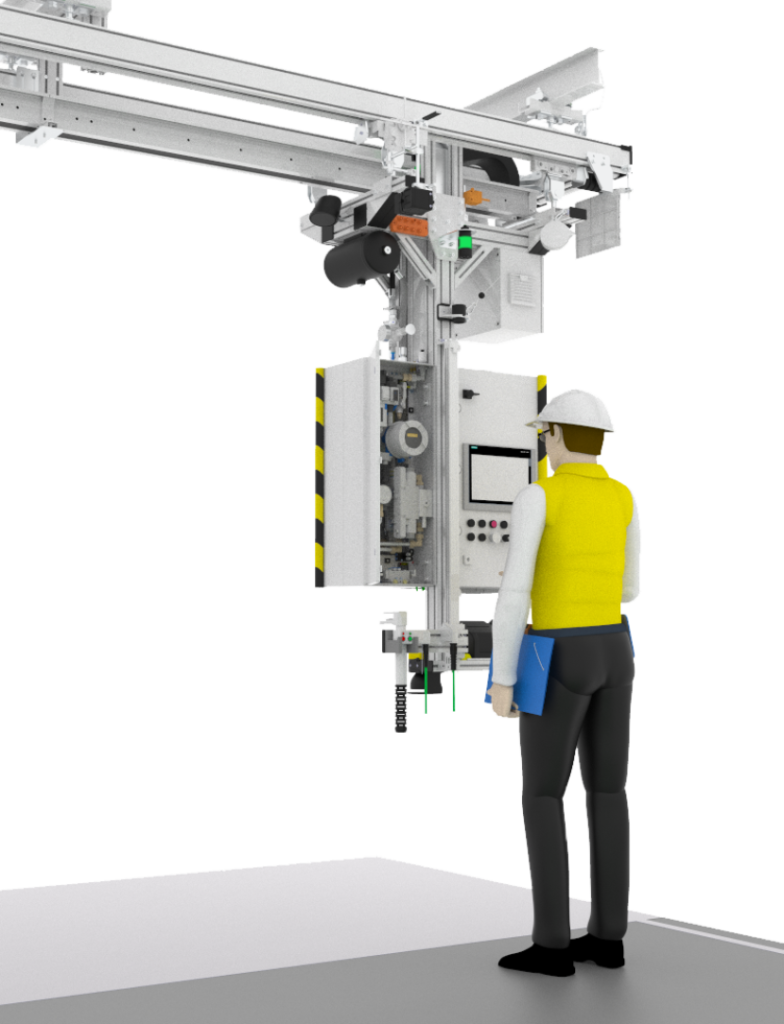

There are two filling brackets themselves. On the right side in the direction of travel of the line there is a console A, on the left side there is a console B. From a technical point of view, these are identical devices, mirror-inverted. The brackets themselves consist of a frame, a pneumatic and electrical switchboard and a filling adapter.

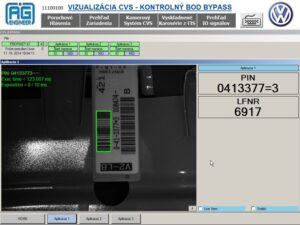

The filling process proceeds as follows. Above the track with EHB hinges is located RFID reader, which is used to read data from the RFID tag, which is located at a designated location on the roof of the body. The visualization panel displays data about the current body. The moment the worker removes the adapter from the holder, the filling console starts running along with the body.

The worker connects the filling adapter to the valve block located behind the rear axle. After connecting the filling adapter and connector, the operator starts the filling process. At the end of the filling process, the worker disconnects the connector with the adapter and puts it in the storage place on the console.

The holder with the adapter and connector is lifted up and the console returns to its basic position by means of automatic reversing.

The filling consoles move along the running rails. On the right side in the direction of travel of the body there is a bracket A, on the left side there is a bracket B. The brackets are identical in terms of functionality. In terms of construction, they are mirror-inverted.

About us

Our company operates in the field of industrial automation. It deals with design, development, design, wiring and filtered engineering, according to customer requirements.

When solving projects, we work with the latest technologies, we provide comprehensive services from design to delivery of equipment to customers. Of course, our work is the delivery of the necessary documentation and training for the operation and maintenance of the supplied equipment.

The company further specializes in the implementation of specific applications, such as integration work and optimization of device functionality. AG Engineer is a guarantee of a complete systematic solution for your production.