ROBOTIC CAMERA SYSTEM FOR VIN NUMBER RECOGNITION

With the increasing number of assembly operations that are performed on the body before the VIN number is marking, the risk increases that there will be a foreign object (cable, hose …) in the place of marking the VIN number. For this reason, it is necessary to check some areas, important for embossing the VIN number, to avoid possible failure, or. equipment / body damage. At the same time, it is necessary to scan the embossed VIN number and store this data in the archive.

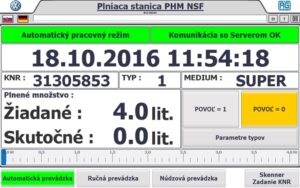

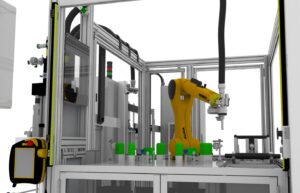

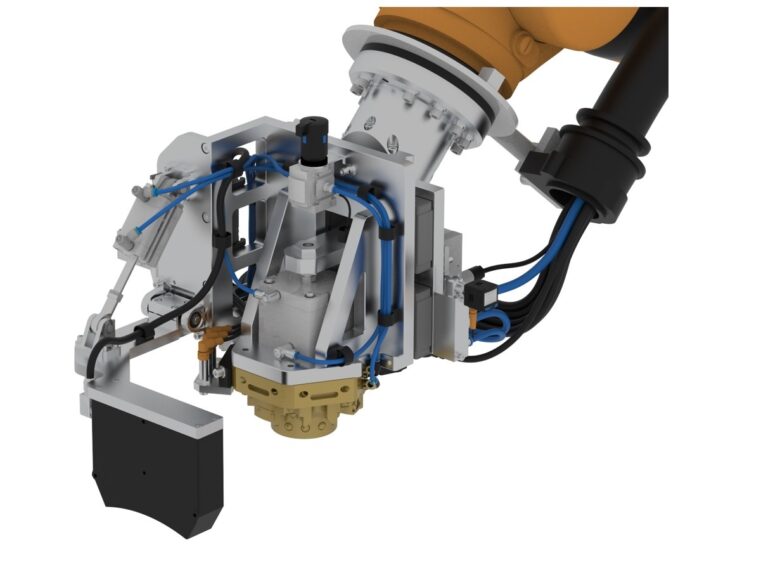

The whole process begins by stopping the skid with the body loaded (Touareg / Q7) on the clock and securing the skid against movement. The robot moves to the waiting position, where it waits for the hood to open. After opening the hood with a device designed for this purpose, the robot with a camera on the tilting arm moves under the front hood, where it performs the measurement. If the camera system evaluates that the area for marking the VIN number is OK, the robot continues to operate – it moves under the hood with the marking head and do the process of marking VIN number.

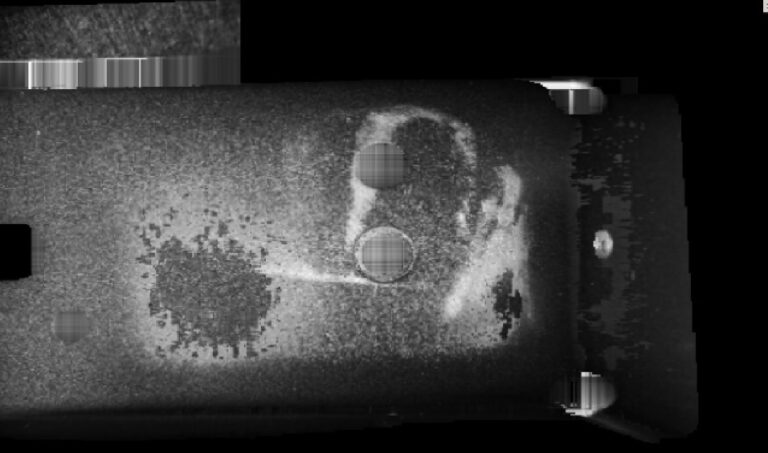

After marking the VIN number, it goes through the number with the cleaning brushes and cleans it with air pressure using a blowing nozzle. After cleaning, the robot moves with the camera over the embossed VIN number, captures the result of the embossing and the images with the embossed VIN number are stored in the archive.

When marking the Audi Q8, the camera system performs two measurements before marking. It controls a large area on which the VIN number is marked and a small area – the bearing surface for the marking head. During shooting, the camera system in the Q8 body is not tilted by means of a pneumatic cylinder – this is not necessary, as the punching point is located on a beam under the seat. The camera is connected to a PC running the VisionAGE VIN H3 application.

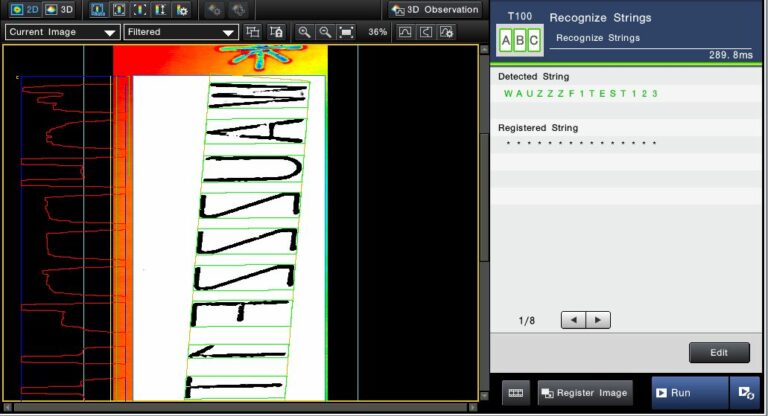

The application provides communication with the camera and evaluation of measurements. The main elements of the application are the display field, the line with status indicators and the panel with information about the body and the camera program.

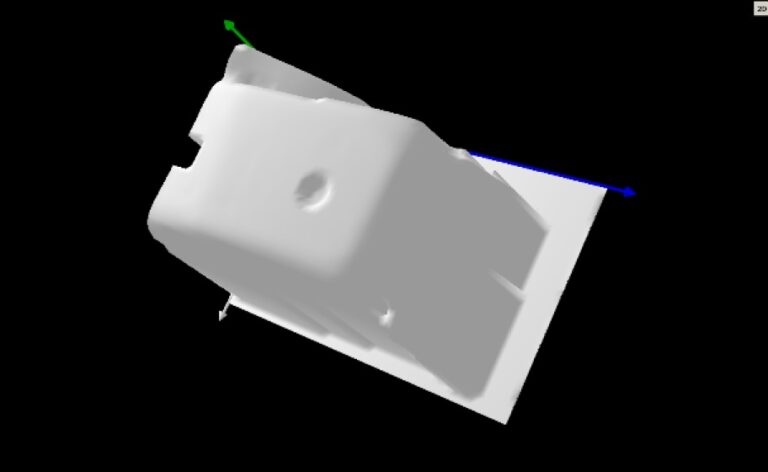

Some of the calculations run in the camera itself, some is performed on a PC in the VisionAGE_H3 application. The result of the measurements is an IO or NIO evaluation of the inspected area. The camera does not compare the measured area with the so-called zero area – this method would be inaccurate, as the skids and body are always in a different position. The camera finds the required area in the space and performs measurements on it. The method consists in measuring the deviations in the Z direction, which means that it looks for objects that are higher (protruding) above the inspected area. If there is a foreign object on the inspected area, the device will declare a fault.

About us

Our company operates in the field of industrial automation. It deals with design, development, design, wiring and filtered engineering, according to customer requirements.

When solving projects, we work with the latest technologies, we provide comprehensive services from design to delivery of equipment to customers. Of course, our work is the delivery of the necessary documentation and training for the operation and maintenance of the supplied equipment.

The company further specializes in the implementation of specific applications, such as integration work and optimization of device functionality. AG Engineer is a guarantee of a complete systematic solution for your production.